- Guaranteed Secure Payments on Every Order

- Refund if your item is not delivered or as described

- Buyer Protection after order confirmation

- Place of Origin: China

- Brand Name: Angong Pump

- Model Number: IH50-32-125

A, IH100-80-160A corrosion-resistant chemical pump "-13,931,139,444 stainless steel chemical pump Product Overview:

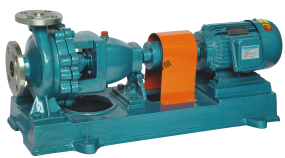

IH stainless steel chemical pump is single stage single suction (axial suction) cantilever centrifugal pump for conveying solid particles with a corrosive liquid viscosity similar to water. Mark, rated performance and size equivalent to international standard ISO2858, having a wide range of performance, high efficiency "three" levels and easy maintenance, its efficiency increased by 5% on average than the F-type pump, the country to promote energy conservation product.

Two, IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 Usage:

IH chemical pump transmission medium temperature -20 ℃ ~ 105 ℃, double seal cooling device when needed, can transport medium temperature of 300 ℃. Used in chemical, petroleum, metallurgy, power, paper, food, pharmaceutical, environmental protection, wastewater treatment and synthetic fiber industries used to transport a variety of corrosive or disallow media similar to water contamination.

Secretary of the products designed and optimized by computer processing, the company has strong technical force, rich production experience and perfect detection means, thus ensuring stable and reliable product quality.

Three, IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 technical parameters:

Flow: 6.3 ~ 400m3 / h;

Head: 5 ~ 132m;

Speed: 2900,1450r / min;

Power: 0.55 ~ 110KW;

Inlet diameter: 50 ~ 200mm;

Maximum working pressure: 1.6Mpa.

Four, IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 Model significance:

IH 80-65-160A

IH - International Standard chemical pump

80-- suction diameter mm

65 - exhaust outlet diameter mm

160 - impeller nominal diameter mm

A - impeller diameter by first cutting

V. Structure Description:

1 IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 pump 2IH100-80-160A corrosion-resistant chemical pump" stainless steel chemical pump impeller 3 IH100-80-160A -13,931,139,444 corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 seal ring 4IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump impeller nut 5 -13,931,139,444 pump cover 6IH100-80-160A corrosion-resistant chemical pump" stainless steel chemical pump seal member 7 -13,931,139,444 intermediate shaft bracket 8 9

Suspension Parts

IH100-80-160A corrosion-resistant chemical pump "steps stainless steel chemical pump -13,931,139,444 overhaul disassembly and assembly and precautions

Removal: IH stainless steel chemical pump due to the coupling structure, the maintenance of internal pump, without dismantling the inlet and outlet piping, pump and motor, just remove the spacer coupling intermediate coupling, can demolition of rotor components.

1. Remove the vent tube on the pump discharge pipe plug on the block body and suspension, put in the net and the suspension liquid pump body oil. (Note: If there is another additional pump tubing should be removed).

2, open the pump and the intermediate coupling bracket and the middle frame, suspension components and pump cover all the rotor components exit together from the pump body.

3. Remove the impeller nut, remove the impeller and key.

4, the pump cover together with bushings, mechanical seals and mechanical seal cover and other components together to exit from the shaft. Be careful not to sleeve with respect to the sliding pump cover, then remove the cover mechanical seals, mechanical seal is removed along with the sleeve together, and then the sleeve and mechanical seal apart. If sealed with packing, you can simply remove the cover from the pump shaft sleeve, and then sequentially remove the packing gland, packing and packing ring. If using a special seal structure, should pay attention to different demolition methods.

5. Remove the middle bracket and suspension bracket.

6. Remove the pump coupling and key.

7, both ends of the suspension before removing dust and bearing plate, cover, and then remove the shaft together with the bearing along the body from the suspension.

8. Remove the bearing from the shaft. Assembly and disassembly procedures were contrary. Starting, running and stopping.

IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump assembly -13,931,139,444: 1 before starting preparation 1) before starting to clean up the site and make pump-clean .2) whether the amount of lubricating oil in the inspection bay right amount (in oil check the oil level gauge centerline before about 2mm) oil level gauge is intact .3) missed coupling the prime mover steering, consistent with the turn arrow after the pump, connect couplings .4) in the installed mechanical seal or Party can make by hand after the filler and the coupling shaft is rotated, the phenomenon should be no grazing, and the coupling guard installed .5) used in pump suction case, irrigation pumps or pumping before starting vacuum; pump in case of intrusion, before starting the application transmission fluid pump filled, get rid of the pump after the air in the discharge pipe valve closed .6) pre-start checks based check for loose screw gland is skew and lubricating oil and cooling water supply.

2. Start 1) Close the import and export pressure gauge and outlet valves (if the bypass pipe, this time should be closed. Starter motor (best to jog, to confirm the correct steering pump after, began formal operation.), And then open the import and export pressure gauge when the pump reaches the normal speed, and the meter indicated the appropriate pressure, and then slowly open the water valve, adjust to the desired conditions. in the case of the discharge pipe is closed, the pump continuous working time can not exceed 3 minutes .2) starting process should always pay attention to the vibration of the motor current and pump vibration number should not be more than 0.06 mm, the measurement site is chock. 3) the seals: mechanical seal should be no leakage, fever phenomenon.

3. Run 1) Always check the pump and motor heating (IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 bearing temperature rise should not exceed 75 ℃) .2) can not be used to regulate the flow of the intake valve, avoid cavitation .3) at the pump should not be lower than 30% of the flow meter Shu continuous operation, if necessary continuous operation under these conditions, should be installed bypass pipe at the outlet, excess flow discharged .4) Note that pump operation without noise, such as found in an abnormal state, should be promptly eliminate or stop checking.

4. Stop 1) IH100-80-160A corrosion-resistant chemical pump "stainless steel chemical pump -13,931,139,444 Slowly close discharge valve outlet pipe and close various instruments switch .2) power off 3) If the seal when an external priming, also turn off external priming valve .4) If the ambient temperature is below the freezing point of the liquid, the liquid net to put the pump, to prevent the cracking .5) If you do not stop for a long time, in addition to the corrosive liquid discharge pump outside the net , disassemble the parts should be cleaned. the pump is best removed after cleaning reassemble, except oiled anti-rust treatment and a closed pump inlet and outlet, but also regular maintenance.

- Place of Origin: China

- Brand Name: Angong Pump

- Model Number: IH50-32-125